Iondrive Secures $100K Grant to Test Metal Recovery from PCBs

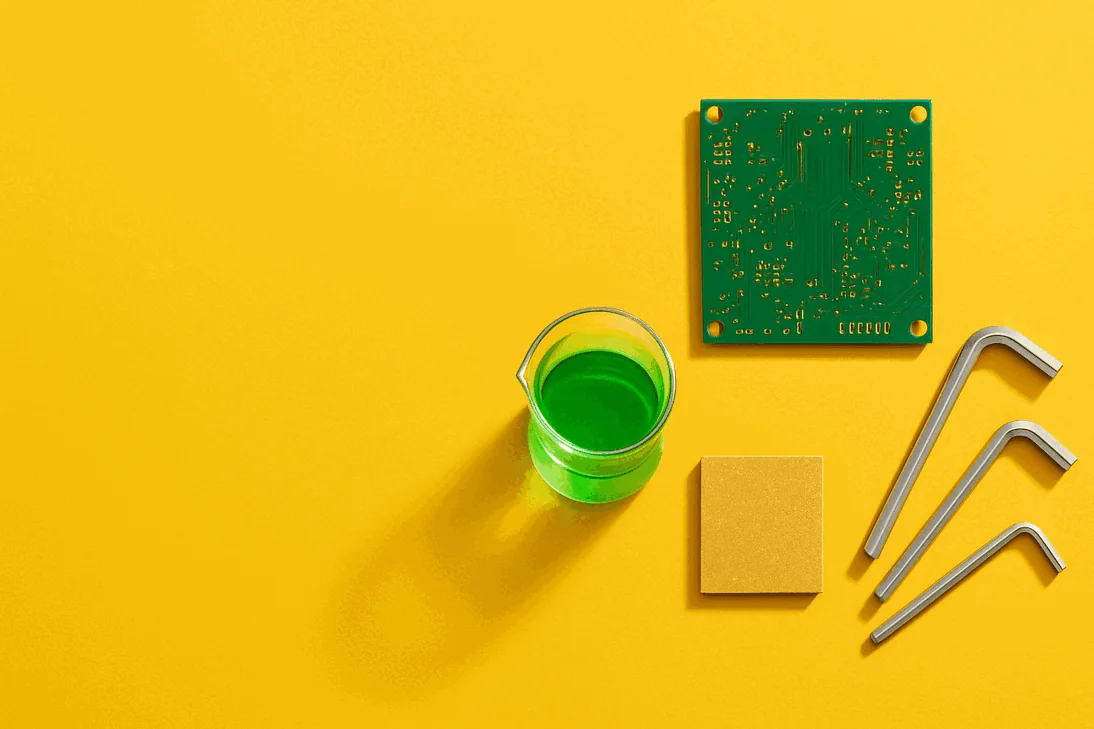

Iondrive Limited is expanding its proprietary Deep Eutectic Solvent technology into the burgeoning e-waste urban mining sector, backed by a South Australian government grant. The company aims to recover valuable metals from printed circuit boards, tapping into a global market worth billions yet largely unrecycled.

- Iondrive to test DES technology on printed circuit boards for metal recovery

- Global e-waste contains $91 billion in recoverable metals with low recycling rates

- South Australian government awards $100,000 grant to support testing

- Project builds on Iondrive’s existing battery recycling platform

- Testing to commence at University of Adelaide in Q3 2025

E-Waste, An Untapped Resource

Electronic waste is one of the fastest growing waste streams worldwide, with global generation reaching an estimated 62 million tonnes in 2022 and projected to rise sharply by 2030. Despite containing an estimated US$91 billion worth of recoverable metals, only about 22% of e-waste is formally recycled. This gap presents a significant opportunity for innovative recovery technologies.

In Australia alone, e-waste generation is notably high, at around 22 kilograms per person annually, more than double the global average. Yet local recycling rates remain low, hampered by limited processing infrastructure and reliance on export chains.

Iondrive’s Strategic Expansion

Iondrive Limited, known for its proprietary Deep Eutectic Solvent (DES) technology initially developed for battery recycling, is now evaluating its application in the urban mining of electronic waste. The company is focusing on printed circuit boards (PCBs), which are rich in valuable metals such as copper, gold, silver, and palladium.

The DES platform offers a sustainable alternative to traditional metal recovery methods, using biodegradable solvents in a closed-loop system that avoids harsh chemicals and high-temperature smelting. This aligns well with circular economy principles and government policies aimed at reducing environmental impact.

Government Support and Testing Plans

Supported by a $100,000 grant from Green Industries SA, Iondrive will commence testing its DES technology on PCBs at the University of Adelaide in the third quarter of 2025. This collaboration aims to validate the technology’s effectiveness in selectively extracting metals from complex e-waste feedstocks and to explore intellectual property opportunities in this new application area.

CEO Ebbe Dommisse highlighted the strategic fit of this expansion, noting the company’s existing infrastructure and expertise will accelerate commercialisation. The move also complements Iondrive’s battery recycling efforts, broadening its addressable market and reinforcing its position in sustainable metal recovery.

Market and Environmental Implications

With global e-waste volumes expected to reach 82 million tonnes annually by 2030, and only a fraction currently recycled, Iondrive’s initiative taps into a vast and underexploited resource. Recovering metals locally from PCBs could reduce environmental harm from mining and waste export, while supporting supply chains for critical minerals.

Should the testing phase prove successful, Iondrive could position itself as a key player in the emerging urban mining sector, leveraging its environmentally friendly DES technology to meet growing demand for sustainable metal recovery solutions.

Bottom Line?

Iondrive’s upcoming test results will be pivotal in determining its role in transforming e-waste into a valuable resource.

Questions in the middle?

- Will Iondrive secure intellectual property rights for DES use in e-waste recycling?

- How quickly can commercial-scale operations be established if testing succeeds?

- What are the potential environmental benefits compared to traditional recycling methods?