Metallium Faces Pressure to Finalize Binding Agreement with Glencore by Year-End

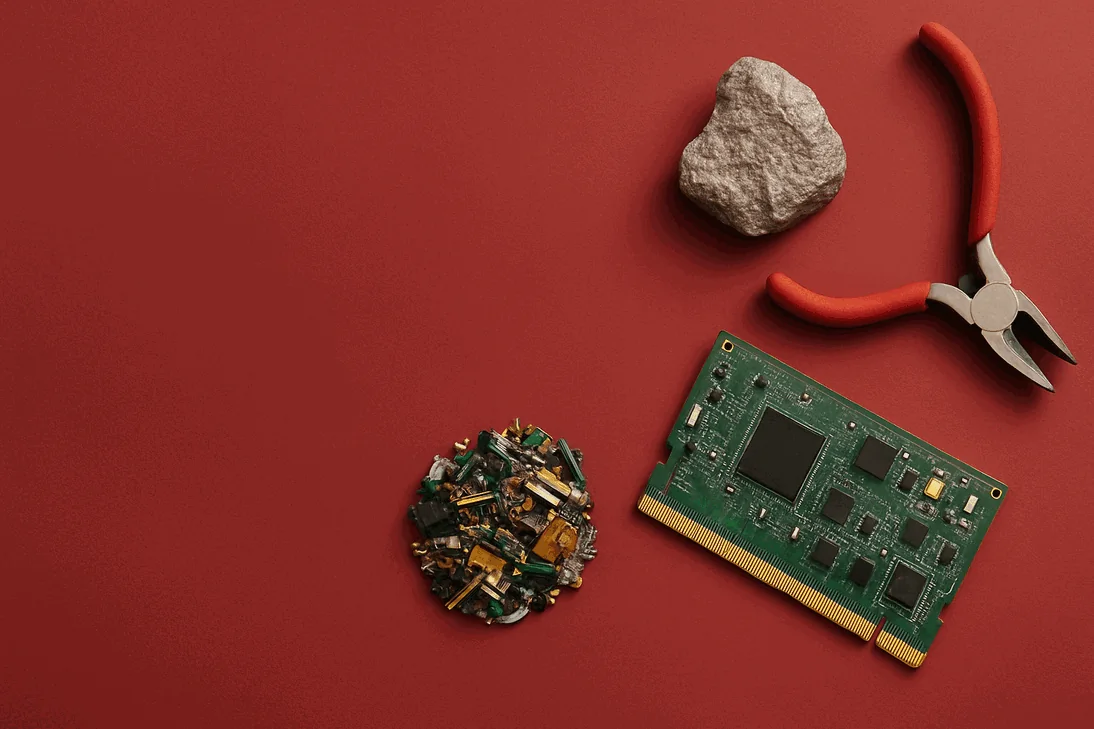

Metallium’s U.S. subsidiary has signed a pivotal Memorandum of Understanding with Glencore, setting the stage for a major supply and offtake partnership in electronic scrap recycling. This collaboration underpins Metallium’s Texas facility launch and validates its proprietary technology in a competitive market.

- Glencore to supply electronic scrap feedstock for Metallium’s Texas facility

- Agreement targets 8,000 tonnes/year of printed circuit board scrap in Stage 1

- Glencore to purchase up to 75% of Metallium’s recycled metal products

- Metallium retains rights to market specialty metals independently

- MOU effective immediately, aiming for binding agreement by end of 2025

A Strategic Alliance in E-Waste Recycling

Metallium Limited, through its U.S. subsidiary Flash Metals USA Inc., has taken a significant step forward by executing a Memorandum of Understanding (MOU) with a subsidiary of Glencore plc, one of the world’s foremost resource and recycling companies. This agreement lays the groundwork for a potentially long-term collaboration focused on the supply of electronic scrap and the offtake of recycled metals in the United States.

Glencore’s commitment to supply feedstock to Metallium’s first commercial facility in Texas is a critical development. The facility aims to process 8,000 tonnes per year of printed circuit board scrap during its initial stage, with potential to scale up as Metallium advances its operations. This feedstock certainty is vital for Metallium’s growth ambitions and operational stability.

Validating Proprietary Technology and Growth Strategy

Beyond supply, Glencore will provide technical assistance, including assaying services, ensuring the quality and consistency of incoming materials. Moreover, Glencore has agreed to purchase up to 75% of Metallium’s marketable recycled products, encompassing metallic metals and chemical derivatives such as metal chlorides and hydroxides. Notably, Metallium retains the right to independently market high-value specialty metals like gallium, germanium, indium, and rare earth elements, preserving strategic flexibility.

Metallium’s CEO Michael Walshe highlighted the significance of this partnership, emphasizing how it validates the company’s proprietary Flash Joule Heating technology and supports its U.S. expansion model. The collaboration positions Metallium alongside a global leader in recycling, enhancing its credibility and market reach.

Building a National Network with Global Potential

The MOU also aligns with Metallium’s broader strategy to develop a national network of e-waste processing hubs strategically located near major collection points, data centre corridors, and industrial logistics zones. This hub-and-spoke approach aims to enable rapid scaling, cost efficiencies, and a resilient domestic supply chain for critical and precious metals.

While the immediate focus is the U.S. market, both parties remain open to exploring a global agreement leveraging Glencore’s extensive international recycling footprint. The MOU is effective immediately and runs through the end of 2025, with a clear intention to finalize binding agreements by year-end.

Implications for the Circular Economy and Supply Chains

Glencore’s Horne Smelter in Quebec, North America’s largest processor of electronic scrap, underscores the scale and expertise Glencore brings to this partnership. Metallium’s engagement with such a heavyweight validates its technology’s role in the circular economy, particularly in recovering critical metals from complex waste streams.

This collaboration not only secures feedstock and offtake channels but also signals Metallium’s emergence as a serious player in the evolving landscape of sustainable resource recovery and supply chain resilience.

Bottom Line?

As Metallium and Glencore move toward a binding agreement, the race to scale U.S. e-waste recycling with innovative technology is heating up.

Questions in the middle?

- Will Metallium expand beyond the initial 8,000 tonnes/year feedstock target?

- How will the partnership impact Metallium’s revenue and production timelines?

- Could this collaboration pave the way for a global recycling agreement?